By comparing the COGM to the revenue generated from selling the product, a company can determine its gross profit margin and assess its financial performance. In summary, COGM links to COGS because COGS is the sum of COGM and the change in finished goods inventory during a given period. Use this information to evaluate the cost and profitability of producing and selling a product and make cost management and resource allocation decisions. COGM represents the total cost of the products that have been manufactured and are ready for sale, excluding the cost of finished goods that are still in inventory. Conversely, COGS represents the cost of the products sold to customers during a given period. The Cost Of Goods Manufactured (COGM) formula is a powerful tool to help managers analyze their company’s production costs.

- Based on this example calculation, the total manufacturing cost for this specific period is $95,000.

- You need to determine the number of finished goods on hand at the end of the previous month.

- Calculating COGM accurately is essential for cost control, pricing strategies, and financial reporting.

- COGM, on the other hand, is a gauge of the manufacturing costs during a specific time period.

- These three primary components make up any business’s total manufacturing cost.

- In practice, most modern manufacturers use MRP software with perpetual inventory systems that calculate WIP automatically and continuously.

- It provides a clear picture of the total production costs and is vital for various financial decisions.

For instance, companies with high overheads might have a minimum level of sales required to stay in business, while those focusing on direct costs won’t depend on such performance requirements. This means that companies sometimes spend slightly more or less money on production than was expected. However, this knowledge can be used to budget better in the future to understand the causes of these differences and aim to reduce costs.

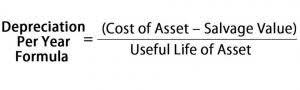

How to Find Cost of Goods Manufactured or Goods Produced (Calculating COGM)?

It encompasses direct materials, direct labor, and overheads, offering a clear picture of where resources are being utilized. This knowledge is essential in pinpointing the primary cost drivers, enabling businesses to implement targeted measures to control and reduce costs. COGM is a term used in managerial accounting that refers to the total cost of producing products and getting them ready for sale during a specific accounting period. It’s an important figure in the manufacturing industry as it directly relates to the efficiency and profitability of production.

- For the COGM, you should only consider overhead costs that directly contribute to product production.

- The beginning WIP is the value of all unfinished products that carried over from the previous accounting period.

- The term “cost of direct labor” refers to the wages, salary, and benefits paid directly to the product’s employees.

- COGM stands for “cost of goods manufactured” and represents the total costs incurred throughout the process of creating a finished product that can be sold to customers.

- The calculation starts with the beginning raw materials inventory, which is the number of raw materials on hand at the beginning of the period.

Whereas COGM depicts the costs of producing all finished goods, COGS only takes into account the costs of producing goods that were sold within the same accounting period. This is important from an accounting point of view as it pinpoints the expense that a company needs to recover per sold product, in order to break even. While accountants can approximate its value at the end of fiscal periods, modern inventory and manufacturing software calculates COGM in real-time, based on actual manufacturing data.

Cost of Goods Manufactured in Accounting and Finance

You can reduce workers’ wages and salaries and hourly rate or make them more efficient in their work, simultaneously boosting the credit side of the balance sheet. With a proper monitoring system like the time logs or a system designed to calculate goods completed or a good manufactured, you can know those employees that are slacking and make proper adjustments. The (COGS) is an essential component that provides a clear picture to business owners and managers about the company’s manufacturing performance. Therefore, 10% of Ben’s monthly revenue will be servicing the company’s overhead rate. Generally, calculating the COGM yields information that will be useful to your business.

Given their names, it’s probably not surprising that they refer to similar things. Just like with total manufacturing cost, though, there is an important distinction. The difference is the first equation has just broken down the “total manufacturing cost” portion of the equation into its components.

Managing Intellectual Property in Contract Manufacturing

The cost of goods manufactured (COGM) is an important metric, especially for manufacturing businesses, because it can affect profitability, which is the ultimate goal of any business. Finished Goods Inventory, as the name suggests, contains any products, goods, or services that are fully ready to be delivered to customers in final form. Beginning and ending balances cost of goods manufactured calculator must also be considered, similar to Raw materials and WIP Inventory. The beginning work in progress (WIP) inventory is the ending WIP balance from the prior accounting period, i.e. the closing carrying balance is carried forward as the beginning balance for the next period. Gross Profit is the difference between the revenue from the sale of goods and the COGM.

Instead, it’s a calculation used within the accounting process to determine the Cost of Goods Sold (COGS), which is a line item on the income statement. Benchmarking COGM against industry standards can offer valuable insights into a company’s cost efficiency relative to its competitors. Internally, tracking COGM over time assists in evaluating the effectiveness of new policies or changes in the production process, helping in continuous performance improvement. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company’s competitive edge. The formula to calculate cost of goods sold is beginning finished goods inventory balance + cost of goods sold minus ending finished goods inventory balance.

Manufacturing overhead refers to the indirect costs that a company incurs during production over a specific period. A Cost of Goods Manufactured Calculator helps businesses in several ways, providing valuable insights into their production costs and aiding in decision-making. It contains many costs like manufacturing costs, Direct material costs, Indirect costs, indirect material costs, indirect expenses etc. Most of these details are tracked shown in Balance Sheet or income statement.

Yes, the cost of goods sold typically includes the cost of goods manufactured. This means that when it comes to managing your manufacturing accounting, all those numbers will already be there and ready to go. If you don’t, you could lose money or even go out of business because of miscalculations and inaccurate information. Luckily, some tools make it easy to calculate COGM and keep track of the results. The COGM formula can be calculated manually or automatically using cloud manufacturing software like Katana.